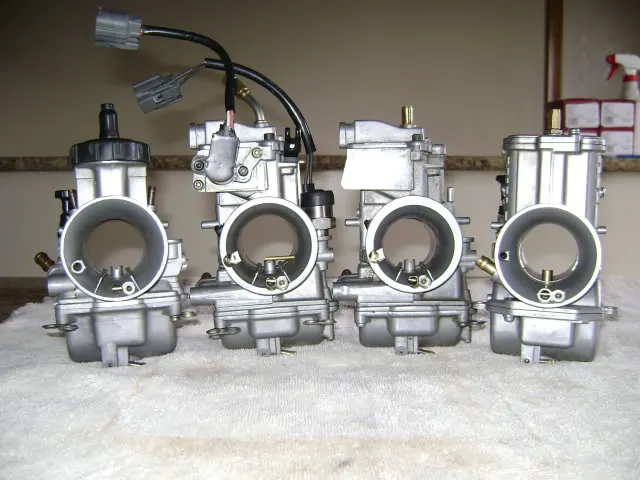

Ever wondered how the carburetor on your 2 stroke dirt bike works? Carbs appear to be complex with all of the tiny jet circuits and passages, but the function has always been simple.

A carburetor for a gas engine has been around since the 19th century, and it basically controls the ratio of air and fuel going into the engine.

I have spent many years tuning the jetting on my own 2 stroke dirt bikes. I started learning about jetting through the internet and have spent countless hours researching how carburetor works.

This article will illustrate how your 2 stroke bike's carb works in simple terms that's easy to understand.

Why Do Engines Need A Carburetor?

For a combustion engine to run, it needs to have a proper mixture of air and fuel.

The internal combustion is like a mini explosion of fuel that pumps the engine to make power. If it doesn't have enough oxygen (air) then it won't be able to burn all of the fuel. Un-burnt fuel will smoke out the exhaust and foul up the spark plug, causing the engine to stop running.

How Does A Carburetor Actually Work?

Once the engine is started, it creates a vacuum that sucks in air through the carb. As air gets sucked past the carb, it pulls fuel through a jet circuit from the float bowl.

Changing the size of the jet affects how much fuel will get sucked through it.

As the throttle slide opens, more air gets sucked through, which pulls more fuel from the float bowl.

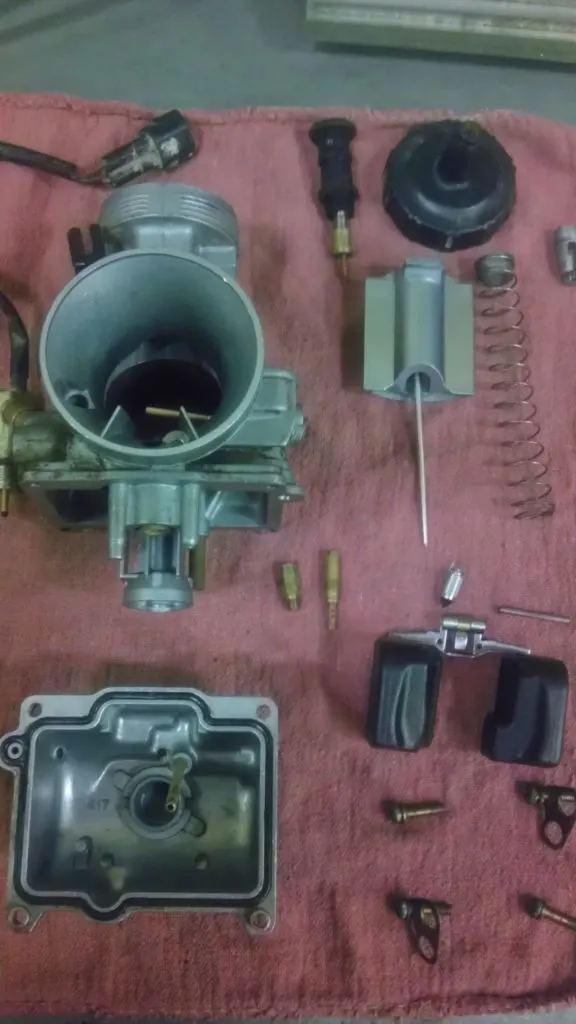

Float

The float is in the float bowl at the bottom of your carburetor. The gas line from the gas tank goes to and fills up the float bowl.

What Is The Needle & Seat In A Carburetor?

To control how much fuel is in the float bowl, the float is attached to a needle that seats against the gas line opening. When fuel is used by the engine, the float will get lower.

This will pull the needle off of the seat and allow gas to fill the bowl back up. Once the float reaches its set height and the needle pushes against the seat, gas will stop flowing in.

This is a constant function to control the amount of fuel in the float bowl.

Why Is The Float Height So Critical?

Fuel that sits in the float bowl is sitting directly under the jet circuits. As the engine sucks the air in, the fuel gets sucked up through a jet circuit. The closer the fuel is (higher float height) to the jets, the more fuel gets sucked through.

This means that the float height affects the jetting of every circuit.

A low float height will allow more air and less fuel into the mixture and result in a leaner running engine.

A higher float height will allow more fuel into the mixture, creating a richer mixture.

Now you see why setting the float height is so important. If the float is off, then it's going to be more difficult to jet all of the circuits.

Changing the float level will require you to re-jet all of the circuits if they were previously jetted "correctly".

To learn how to properly set the float height on your 2 stroke carburetor read this article.

Idle Screw

The idle screw is not a jet circuit. It's simply a specially designed screw that adjusts the height of the throttle slide when "closed".

The throttle slide always stays open a small amount because air needs to get through the carb to keep the engine running.

The idle screw simply makes this gap smaller or bigger to change the idle speed of your engine while running.

The idle speed should be set when your engine is fully warmed up.

A hot engine burns the air-fuel mixture better than a cold engine. If you set the idle when the engine is cold, the idle will decrease as the engine warms up.

Pilot Jet

The pilot jet meters (controls) the amount of fuel that mixes with the air when the throttle is 0-¼ turn open.

The pilot jet is the smaller jet circuit and is one of the most important factors to making your 2 stroke run well. It’s the circuit that is primarily used for starting your bike, as well as throttle response at small throttle openings.

The pilot jet (may also be called a “slow jet”) can be fine tuned as weather or elevation changes throughout the day, which we’ll look at in a minute.

Being such a tiny hole, the pilot jet can easily get plugged up with dirt from the fuel, or from old fuel that deteriorates and causes the brass jets to turn green. It will eventually form a “gunk” that partially or completely blocks the jet passage, making it difficult or impossible to start the engine.

Air Screw

The air screw (or pilot air screw) is the “fine tuning” part of the pilot jet. It is a smaller adjustment that allows more or less air through when fuel is being sucked through the pilot jet at low throttle openings.

The air screw adjustment is recorded as “number of turns out”. Turning the screw all the way in (clockwise), just like you would tighten a screw or bolt is defined as “0 turns out”. Turn it out (counterclockwise) one full turn and it’s at “1.0 turns out”.

2.0 turns out will allow more air through than 1.0 turns out, making it a leaner air-fuel mixture.

The total adjustment ranges from 0-3 turns out.

Ideally, you want to be at 1.5 turns out on a given day, that way you have adjustment on both sides of you need to go richer or leaner throughout your day of riding.

Needle

The needle is a very important part of jetting because it affects the largest range of throttle openings.

Actual needle tuning can get very complex compared to a basic jet that simply gets bigger or smaller in size. Needles can come with different sizes, taper angles, and number of tapers.

What Does The Needle Do?

The pilot jet controls the fuel at idle and small openings, while the needle controls the fuel at openings past that.

The needle jet goes through the throttle slide and into the main jet circuit. As you can see in the picture, the needle has a taper that get smaller towards the bottom. As the throttle opens more, the diameter that controls the amount of fuel entering the mixture gets smaller, which allows more fuel through.

How Do You Adjust The Needle?

Adjusting the needle is as simple as changing the position that the clip is in. Most needles have 5 clip positions. Stock or standard is the middle, while the top position is the leanest and the bottom slot is the richest position.

What Does Needle Clip Position Do?

The needle clip is what sets the height of the needle in the emulsion tube. The top clip position is the leanest because it sets the needle down the furthest. Since the needle is tapered, it takes a bigger throttle opening to reach the same needle position as a lower (richer) clip position.

Needle Tuning For Beginners

To keep things simple, just use the stock needle that comes in your bike from the factory. It's best if it has multiple clip positions because that's where you'll move to next for tuning.

Slide

The slide in a carburetor is what opens and closes to allow air through to the engine. It is attached to the throttle cable. As you turn the throttle, the slide raises and increases the amount of air capable of flowing through.

Aside from swapping to a carb with a different style of slide (flat-slide, round-slide D-slide), there's only 1 significant thing you can tune on it. The only problem is that it's a permanent change because you're removing material. I only recommend this modification to experienced jetting tuners that know what they are doing and what will result in this change.

Main Jet

The main jet is the largest jet and is generally very easy to remove and replace for tuning purposes. It's the circuit that controls the fuel mixture around ½ to full throttle.

There is some overlap amongst the jet circuits. The main jet is the most important for reaching maximum peak horsepower.

It’s not as critical as tuning the pilot and needle if you’re just a casual trail rider that is less aggressive on the throttle.

On the flip side, if you like to whack the throttle and hold it wide open for long periods of time, racing or not, you need to properly dial in the main jet. Having it too lean will burn the piston down, but too rich and it will be sputtering with poor acceleration.

Vent Hoses

The vent hoses on your 2 stroke carb are simply to get rid of excess fuel in case the carburetor floods. This most often happens when you tip your bike over and some gas spills out of one of the hoses.

The overflow hose is in the float bowl. If gas is leaking out the overflow hose then the float height is either set too high or the needle and seat are leaking fuel into the carb bowl.

Any Special Carb Adjustment Tools Required?

You can use basic screwdrivers that are appropriately sized for most 2 stroke carburetors.

However, I have found that having a drain plug wrench and a main jet tool very handy for trail rides. They are both extremely small and lightweight compared to standard tools and work just about as well if you don’t over tighten the plug or jet.

Common 2 Stroke Carb Problems:

- Dirty carb/pilot jet

- How to rebuild a 2 stroke carb

- Flooding

- Leaking Gas

- Running Rich

- Running Lean

- Bogging

Now that you understand how your 2 stroke carburetor works, it's time to get the most power and efficiency out of it. Click here to learn how to start tuning it for better power & reliability in minutes.