Wondering if the valves need to be adjusted on your 4 stroke dirt bike or how much it might cost? Letting them go too long can turn into major engine problems, but let's figure out this problem before it gets that far.

In this article, I'll show you the most common symptoms of a 4 stroke dirt bike that needs the valves adjusted, what causes it, how much you it will likely cost, how to help prevent it, and how often you should be doing this routine maintenance.

What Happens When You Don’t Do A Valve Adjustment?

Aside from the symptoms above, not adjusting your dirt bike valves can and will bring bigger consequences.

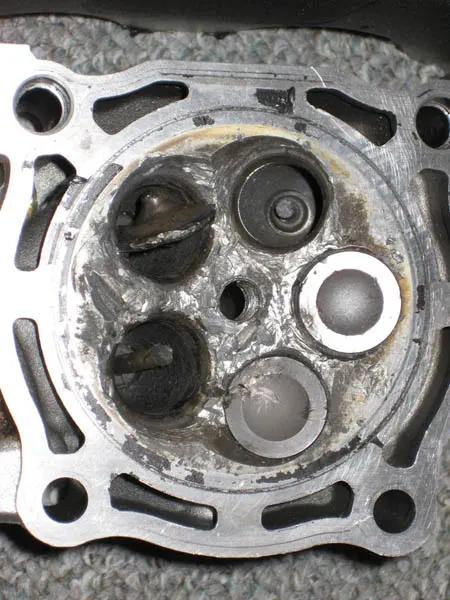

If you're fortunate, the valve will just burn enough away to lose compression and the engine will stop running.

In a serious event, the valve could hit the piston, causing the engine to seize or pick-up in a split second.

How to tell if your dirt bike needs a valve adjustment

The only way to know for sure if your dirt bike needs a valve adjustment is to check the valve clearance, but I want to give you the most common signs that it might be needed before you waste your time removing parts to get to the valves.

If you have most or all of the symptoms listed below then you can deduce that a valve adjustment is probably needed, but you really needed to check to see if the clearances are in or out of factory given specifications.

These are the most common 4 stroke valve adjustment symptoms on a dirt bike:

Hard to start

When the intake valves get too tight, meaning there's zero clearance between the valve stem and the rocker or bucket/shim, the valve won't properly seal. This reduces the amount of static compression while cranking, making it hard to start when cold. So, instead of 1-3 kicks, it may take 10-20 kicks to start when cold.

The valve clearance may also be tighter when the engine is hot because the valvetrain parts have expanded, giving you less compression and hard to start.

How to start it when it won't kick-start cold

If your dirt bike valves are tight and need an adjustment, you can sometimes start it more easily by doing a simple bump-start. This rotates the engine fast enough to get it fired and running.

Popping in deceleration

Popping on deceleration is often a lean jetting condition, but it can be caused by a valve problem. When the exhaust valves aren't sealing well, unburned fuel in the combustion chamber can escape and then ignite in the exhaust system. This causes the popping/backfiring noise.

Loss of power

If your 4 stroke dirt bike suddenly loses a lot or all power, there's a good chance that the valves are the issue. Rather than needing an adjustment, at least one valve likely needs to be replaced because it burned away enough material and can't properly seal against the cylinder head, causing a loss of compression.

This is not to be confused with an engine seizure, which is when the engine makes a loud or grinding noise, dies, and is locked up so that you can't even kick the engine over. When a valve burns up or goes out of adjustment, you can still turn the engine over.

Misfire

A misfire is simply a hiccup or hesitation while your engine is running, and this can be very dangerous while riding. If you need to accelerate and it bogs or hesitates, you may not be able to ride over an obstacle or get up a hill, causing you to crash and get hurt, even if you're a good trail rider.

A misfire can be caused by several things, but it's one symptom of dirt bike valves that need to be adjusted.

Hanging idle

Handing idle or high idle that's slow to stabilize is one symptom of tight intake valves that need to be adjusted. When you give it gas and it takes several seconds to get back down to an idle - that can be caused by valves out of adjustment, an air leak, or lean jetting.

If you've already tried adjusting the jetting and confirmed that there are no air leaks in the intake or exhaust and still get a hanging idle, then it might be time to inspect and/or replace one or all of the valves.

Lower compression

When the valves are tight, meaning little to no clearance, they're always being pushed away from the cylinder head. This gives you a low compression symptom because air is leaking past the valve and into the combustion chamber.

What Causes Valves To Go Out Of Adjustment?

Depending how what type of valve train your 4 stroke dirt bike has, certain parts simply wear out. Each manufacturer has set limits or tolerances of how much clearance each valve should have.

Once the clearance is above or below that tolerance, you will generally start noticing symptoms. Hard to start or backfiring are some of the most common.

Titanium vs stainless valves durability

A titanium valve has a special coating that is made to increase durability. Once that coating goes away the valve will quickly go out of adjustment. Normal wear and heat will burn the coating away over time.

A stainless steel valve generally doesn't have a coating, but it still wears out for the same reason; wear and heat.

Which is better? Stainless dirt bike valves generally last longer because they can't withstand more heat, but they're also quite a bit heavier. Titanium valves are the best choice for performance because less weight = more power because the engine can rev faster.

What exactly is a dirt bike valve adjustment?

A valve adjustment is when you make the valve clearance tighter or looser by adjusting the rocker arm tappet or valve shims to get the proper amount of clearance. Most dirt bikes or motorcycles require you to take the seat, gas tank, and cylinder head or valve access hole to inspect or adjust the valve clearance.

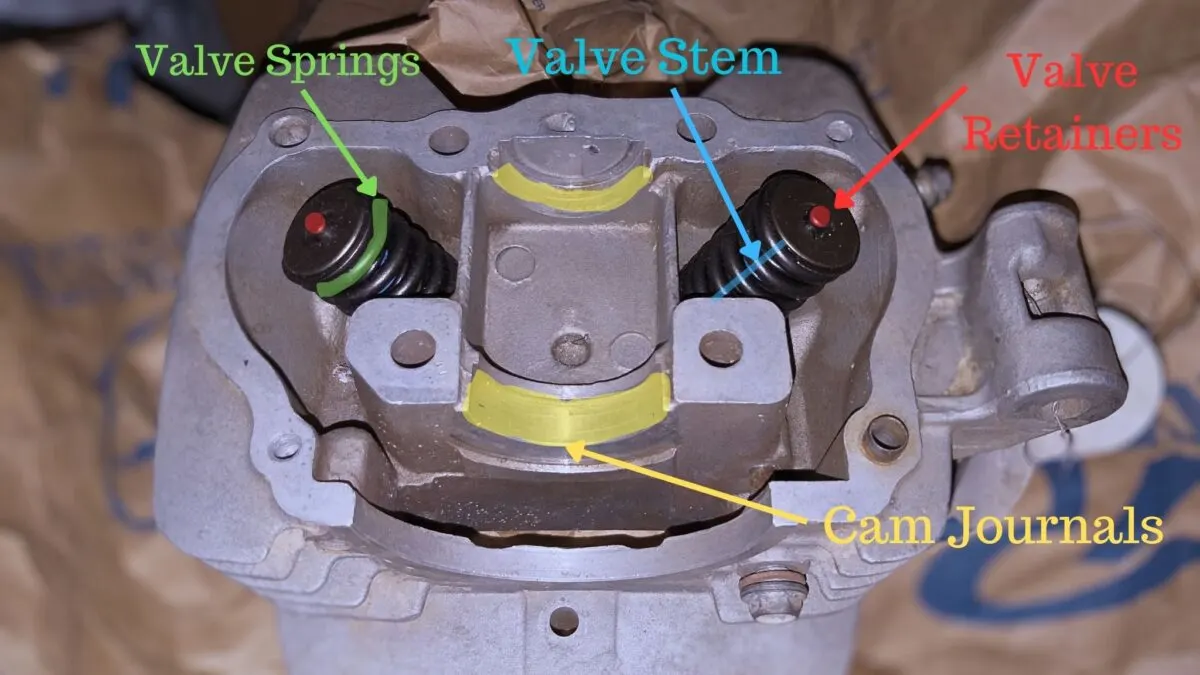

What is valve clearance?

Whether it's a dirt bike, pit bike, or motorcycle, 4-stroke valve clearance is the amount of gap between the camshaft and valve tappet or shim bucket, depending on the style of the engine. There needs to be a proper amount of clearance or gap so that oil can get between the parts.

As seen below, the rocker arm pushes down on the valve retainers as the cam rotates - the valve clearance is between the retainer and the rocker arm finger.

If there's not enough clearance, then the cam, valve tappet, and/or shim bucket can starve from not enough oil, which will cause them to overheat quickly from too much friction - this is when you might start hearing a ticking noise.

The worst-case scenario is if it gets so hot that the parts start to melt and seize together.

How Much Does A Valve Adjustment Cost?

A typical shop will charge about $150 to adjust the valves on your 4 stroke dirt bike. This is because it's quoted as a 2 hour job at an average $75/hour shop rate.

Learning how to do it yourself can save a lot of that money, depending on the tools you already have. Valve shims are expensive if you buy a kit, but they should last for years and multiple bikes.

How Do You Adjust Dirt Bike Valves?

Adjusting valves is not as complicated as it sounds on most dirt bikes. The most time-consuming part is often just removing other parts to get access to the top of the cylinder head.

When checking valve clearance, your engine needs to be cool to the touch and the piston resting at TDC (top-dead-center). Most dirt bike engines have an inspection hole plug that can be removed on the flywheel cover (left engine case) so that you can see markings where the piston is in the cylinder.

Tappet-Valve Adjustment

A 4 stroke dirt bike that has a rocker arm/tappet valve train is pretty simple to adjust. It's older technology, mostly in air-cooled bikes, but it still works well.

There will be a locking nut that holds the tappet adjuster. Break that loose and then you can tighten or loosen the adjuster.

Use a feeler gauge to check the clearance between the rocker arm tappet and the valve. Adjust to the specified clearance given by the factory.

This must be checked when everything is properly torqued to spec and the engine is cold.

Proper valve clearance example (Yamaha YZ250F):

- Intake: .004 to .006 inches (.1 to .15mm)

- Exhaust: .007 to .009 inches (.17 to .22mm)

Every dirt bike engine may be slightly different, so be sure to refer to your OEM service manual for exact specs for intake and exhaust valve clearances. If you're using an aftermarket camshaft with different specs, refer to the camshaft manufacturer for proper clearance specs.

Shim & Bucket Valve Adjustment

Most motocross and enduro 4 stroke dirt bikes have a shim and bucket valve train. They are similar in how to check the clearance.

You use a feeler gauge to check the valve clearance. To adjust it, you must have a shim kit and adjust the shims to get the right height under the bucket.

Bad valve adjustment symptoms

Whether you decide to adjust the valves yourself or pay someone to do it, it's important to pay attention to potential signs that the valve adjustment was done incorrectly, which can lead to major problems quickly, such as the valves hitting the piston and requiring a top-end rebuild.

Here are some basic symptoms of a bad valve clearance adjustment:

- Hard to start

- Ticking noise

- Lack of performance

- Excessive wear on valvetrain parts

How Often Should Valves Be Adjusted?

According to my Yamaha manual, a YZ250F should have the valve clearance checked every 500 km (300 miles) or every third race - that would roughly be every 10-20 hours.

Is this really necessary? If you are an expert level motocross racer, then I'd say yes. However, most riders do not need to check them nearly as often, depending on how you ride.

Checking them on a routine schedule can be a good idea to prevent a possible failure.

Valves only need to be adjusted when they are out of spec. Once you start noticing one or multiple symptoms listed in this article, it's time to check valve clearances.

If you're regularly hitting the reg limiter on a 250F then you're going to need to check and/or adjust them a lot more often than if you're casually trail riding at lower RPMs.

How Long Do Dirt Bike Valves Last?

Now that is a loaded question. The valves in your 4 stroke will last as long as they stay within spec and properly seal against the valve seat.

If you're looking for a number of hours, there's no set number that you can count on needing to replace them.

You, as the owner and rider of your dirt bike need to know what your bike is doing and how it sounds when you ride it.

There are ways to tell when something needs attention. The symptoms listed above will let you know when the valves are most likely to need adjustment.

If you need to adjust the valves multiple times in a short amount of time, then it's time to replace the valves and possibly get other head work done because the valves probably wore out the seats on the head.

Does A Valve Adjustment Improve Performance?

Adjusting the valves to proper specifications can make a slight improvement in power. The biggest improvement will be the negation of symptoms.

If your dirt bike was hard to start, then it will be easier to start after adjusting the valves. Misfiring should go away if that was a symptom.

Unless the valves were way out of spec, in which your bike probably wouldn't run anyway, you're not going to feel a huge gain in power.

With that said, reliability is the most important reason you need to adjust the valves if they are out of tolerance.

Can Valve Clearance Affect Compression?

Valve clearance can affect compression. If one or more valves are out of adjustment, it may be open during the engine combustion cycle when it’s supposed to be closed.

This creates a small leak-by because the valve isn’t fully sealing against the valve seat. This leak will cause a drop in compression.

Do Valves Get Tighter Or Looser?

Generally, valves will get tighter as they wear. They can get looser if something else becomes loose in the cylinder, but that is rare.

The most common symptoms of tight valves in a 4 stroke dirt bike or motorcycle are:

- Hard to start

- Won't stay idling/rough idle

- Worn-out valves that need frequent adjustment or replacement

Symptoms of loose valve clearance:

- Noisy/ticking sound

- Slight drop in performance

A little bit of valve tapping noise can be normal, especially on an older air-cooled 4-stroke engine. If this ticking noise gets louder or turns into a knocking noise, then it's time to shut it off and start troubleshooting.

Why Do Exhaust Valves Get Tighter?

As a valve wears, it will sink into the valve seat and get closer to the cam, thus making it a tighter clearance.

The valve seat can also wear out from the valve hitting so many times. This causes the valve to sink into the cylinder head.

Valves seats can be re-cut for better seal and performance, but it’s better to replace the seat if it’s sunk in too far.

How To Make Valves Last Longer

The two biggest factors that affect the longevity of the valves in your dirt bike are how you ride and how well you maintain the bike.

Valves wear out because of heat and wear. There are some easy ways to prevent premature wear. There are other ways that are simply not reasonable. More on this in a minute.

Common Causes That Wear Out Valves Quicker:

- Lean Jetting

- Overheating the engine

- Idling for long periods of time

- Riding at high RPM

- Constantly hitting the rev limiter

- Not keeping the air filter clean

- Higher power output

Jetting For Reliability

Leaner jetting can mean more power, especially if the air/fuel ratio is too rich. However, going too lean will create too much heat.

This heat increases the wear on all the internal parts. Valves can lose their coating and/or seal because they burn away over time.

This is why it's so important to learn how to jet your dirt bike. Using a fuel controller is becoming a standard practice as well with the fuel injected motocross bikes.

Overheating Is A Killer

As mentioned, heat is the enemy of valves. Whether it's lean jetting, or idling too long, you need to know how hot your 4 stroke is getting - steaming and a loss of coolant is a sure sign that it's getting too hot!

Overheating is actually a fairly common problem, but if you let it happen on a regular basis, the engine is going to take a toll. Learn more about overheating here and how to prevent it.

How Do You Ride?

Do you ride your dirt bike to its full potential? Most riders don't, but many like to sound like it…

Riding at a high RPM not only sounds cool, but most bikes produce high horsepower numbers at high RPM. There is a point where power tapers off and goes down. The rev limiter then kicks in shortly after.

Riding in the upper RPM range is often mandatory while racing if you want to go fast. With that said, constantly hitting the rev limiter is not. It's there for protection so the engine doesn't over-rev and break parts from spinning to fast.

If you like hitting the rev limiter just to hear it, do your bike a favor and stop. Not only is there less power at redline RPM, but you're wearing out the valve train faster.

The valves are moving faster and hitting the valve seats harder when they come back to deal against the head.

How To Maintain Your 4-Stroke Engine

To make your dirt bike last as long as possible, properly maintaining it is the most important thing to do. Regular oil changes when it gets dirty, and keeping an eye on how the oil looks.

Are you seeing a lot of metal flakes in the oil? That's a sign that something is probably wearing out faster than it should.

Keeping the air filter clean is crucial to making the valves last longer. A dirty or improperly oiled air filter will allow dirt to pass through the engine.

Dirt will eat up engine parts. It may not happen overnight, but the engine rebuild intervals can be greatly increased if you keep clean air going through the engine.

Is It Better To Have More Power?

You can never have enough power, right? Well, as much fun as having mega horsepower can be, whether it's more efficient or not, there is a downside.

More power equals more heat. Yep, that means that the faster your bike is, the more heat it will potentially create. This is why keeping it cool can prevent a lot of problems.

Modifying a dirt bike to go faster doesn’t necessarily make it less reliable. It’s when you use the extra horsepower that things start to wear out slightly quicker.

Bottom Line:

If your 4 stroke is hard to start, pops/backfires, or is low on power, then it might be time to adjust or replace the valves. To make valves last longer, keep your engine running cool and properly maintain it.

These things will make your dirt bike last for many hours or years to come.

4 strokes tend to run at a higher operating temperature than a 2 stroke. This can result in overheating problems.

The radiators not getting enough air to cool it down is a common issue. For more symptoms of an overheating dirt bike and how to fix it to prevent long-term problems click here.

The most common signs of a 4 stroke dirt bike that needs valves adjusted are:

- Hard to start when cold

- Popping in deceleration

- Loss of power

- Misfire

- Hanging idle

- Lower compression

Trail riding with confidence made easy

It's not hard to ride a dirt bike, but riding with confidence and control off-road isn't easy... Unless you have the right tools.

No, I don't mean a t-handle and impact gun, but rather the tools to riding with success - balance and control.

It takes balance and learning proper riding techniques to confidently ride trails or out in the bush, and I want to show you how to learn these skills quickly. Tap here for my free training guide.